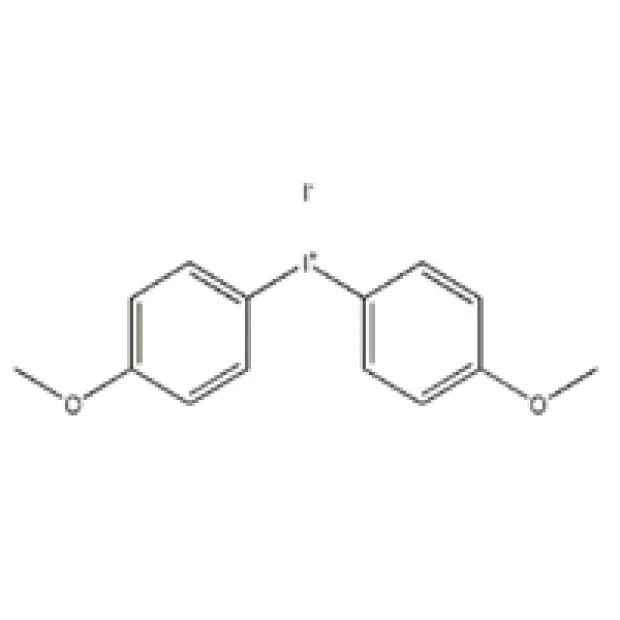

In the rapidly evolving landscape of advanced materials and manufacturing, the demand for high-efficiency, rapid-curing, and environmentally conscious solutions has never been greater. At the forefront of this revolution are cationic photoinitiators, a class of compounds that enable the polymerization of key monomers upon exposure to UV light. Among these, Iodonium, Bis(4-Methoxyphenyl)-, Iodide (CAS: 34123-59-6) from HBGX Chemical stands as a paragon of performance and reliability, empowering industries from 3D printing to high-performance coatings.

This comprehensive guide delves into the world of this remarkable Iodonium salt, exploring its technical superiority, manufacturing excellence, diverse applications, and the unwavering commitment to quality that defines HBGX Chemical as a market leader.

The global push towards sustainability and process efficiency is reshaping chemical manufacturing. UV-curing technology is a cornerstone of this shift, offering significant advantages over traditional thermal curing methods, including reduced energy consumption, elimination of volatile organic compounds (VOCs), and dramatically increased production speeds. Market analysis projects the global photoinitiator market to grow at a CAGR of over 8.5% through 2028, with cationic photoinitiators like diaryl-Iodonium salts carving out a significant share due to their unique technical merits.

Industries like aerospace, automotive, and electronics require materials with exceptional durability, chemical resistance, and thermal stability. Cationic polymerization, initiated by Iodonium salts, is uniquely suited for curing epoxy, oxetane, and vinyl ether resins, which form highly cross-linked, robust polymer networks. This "dark cure" capability, where polymerization continues even after the UV light source is removed, ensures complete and thorough curing, a critical factor for performance-driven applications.

Stereolithography (SLA), Digital Light Processing (DLP), and other vat polymerization 3D printing technologies rely heavily on photoinitiators. Iodonium salts are preferred for their ability to cure thicker layers, reduce shrinkage and warping, and produce parts with superior mechanical properties and dimensional accuracy. As 3D printing moves from prototyping to mass production, the demand for reliable, high-performance initiators like Bis(4-methoxyphenyl)iodonium iodide is exploding.

With increasing scrutiny from bodies like the EPA and ECHA, manufacturers are seeking solutions that minimize environmental impact. UV curing with Iodonium photoinitiators is an inherently "green" technology. It operates in 100% solid systems, eliminating the need for solvents and thus eradicating VOC emissions. This not only aids in regulatory compliance but also enhances workplace safety.

To truly appreciate the value of this product, a look at its technical specifications is essential. Unlike generic alternatives, HBGX Chemical's Iodonium, Bis(4-Methoxyphenyl)-, Iodide is produced under stringent quality controls, ensuring industry-leading purity and consistency.

| Parameter | Specification | Significance & Expertise Note |

|---|---|---|

| Product Name | Iodonium, Bis(4-Methoxyphenyl)-, Iodide | A diaryliodonium salt specifically engineered for high-efficiency cationic polymerization. |

| CAS Number | 34123-59-6 | Unique identifier for substance registration and regulatory compliance (e.g., REACH, TSCA). |

| Molecular Formula | C₁₄H₁₄IO₂⁺ · I⁻ | The structure contains two methoxy-substituted phenyl rings, enhancing its solubility and reactivity. |

| Molecular Weight | 468.07 g/mol | Critical for calculating formulation percentages and stoichiometric ratios. |

| Appearance | Light yellow to yellow crystalline powder | Color is an initial indicator of purity; minimal coloration is desired for optically clear applications. |

| Purity (HPLC) | ≥ 99.0% | High-Performance Liquid Chromatography (HPLC) confirms the absence of impurities that could hinder polymerization or cause yellowing. This is a key HBGX quality guarantee. |

| Absorption Maximum (λmax) | ~245 nm, ~305 nm | Determines the optimal wavelength for the UV light source. Can be photosensitized to respond to longer wavelengths (e.g., 365 nm, 405 nm). |

| Melting Point | 145-155 °C (dec.) | Indicates thermal stability. A high decomposition temperature is crucial for preventing premature initiation during formulation and storage. |

| Solubility | Slightly soluble in acetone, DMF, DMSO. | Dictates its compatibility with various resin systems and solvents. |

| Shelf Life | 24 Months (under recommended storage) | A testament to the product's stability and our rigorous manufacturing process. |

The superior performance of our Iodonium salt is not accidental; it is the direct result of a meticulously controlled, multi-stage synthesis and purification process, all conducted within our ISO 9001:2015 certified facilities. This is not simple mixing; it is precision organic chemistry at an industrial scale.

High-purity Anisole (methoxybenzene) is reacted with an oxidizing agent and an iodine source under precisely controlled temperature and pH conditions. This step is critical for forming the core C-I-C bond of the Iodonium cation. We utilize high-grade, traceable raw materials to ensure a clean reaction profile from the outset.

The intermediate from Step 1 undergoes a reaction to form the Bis(4-methoxyphenyl)iodonium cation, paired with a temporary counter-anion. Real-time process monitoring via spectroscopy ensures the reaction proceeds to completion, maximizing yield and minimizing by-products.

The salt is then treated with a high-purity source of Iodide ions (e.g., Potassium Iodide) in a controlled precipitation process. This step is crucial, as the counter-anion (I⁻) directly influences the salt's solubility, stability, and initiating efficiency. The exchange must be complete to ensure product consistency.

The crude product is subjected to a series of recrystallization and washing steps. This removes any unreacted starting materials, inorganic salts, and organic by-products. The choice of solvents and temperatures is optimized to achieve the highest possible purity without degrading the final product.

Every batch is tested against our strict specifications. This includes:

• HPLC Analysis: To certify purity ≥ 99.0%.

• FT-IR & NMR Spectroscopy: To confirm chemical structure.

• Melting Point Analysis: To verify thermal properties.

• UV-Vis Spectroscopy: To confirm absorption characteristics.

Only batches that pass all tests are approved, vacuum-sealed in multi-layer, light-blocking packaging, and issued a detailed Certificate of Analysis (COA).

Why choose HBGX Chemical's Iodonium, Bis(4-Methoxyphenyl)-, Iodide? The benefits extend beyond a simple datasheet, translating into real-world manufacturing advantages.

| Feature | HBGX Chemical | Generic Competitors |

|---|---|---|

| Purity Guarantee | ≥ 99.0% (HPLC Certified) | Often 97-98%, variable |

| Batch Consistency | Strictly Controlled (COA with every batch) | Inconsistent, can lead to process adjustments |

| Technical Support | Expert formulation & application support | Limited or non-existent |

| Supply Chain | Stable, scalable production, global logistics | Often relies on traders, risk of disruption |

| Traceability | Full lot traceability from raw material to final product | Often untraceable |

The versatility of Iodonium, Bis(4-methoxyphenyl)-, iodide makes it an indispensable component in a wide array of high-tech industries. We work closely with our clients to provide not just a product, but a complete solution.

We understand that one size does not fit all. HBGX Chemical offers collaborative services to tailor our solutions to your specific needs. This includes:

A leading manufacturer of medical-grade catheters was using a thermal-curing epoxy adhesive to bond a plastic hub to a polymer tube. The process was slow, energy-intensive, and the high temperatures risked damaging the sensitive polymer components. They needed a faster, room-temperature curing solution that met strict biocompatibility standards.

HBGX Chemical's technical team collaborated with the client. We recommended a formulation based on a biocompatible epoxy resin initiated by our high-purity Iodonium, Bis(4-methoxyphenyl)-, iodide. We helped them select a suitable photosensitizer to make the system highly reactive to their 395 nm LED curing equipment.

The implementation was a resounding success:

"Working with HBGX Chemical transformed our assembly line. Their Iodonium photoinitiator was the key. Not only is the product top-tier, but their technical support was invaluable in helping us optimize the process. Our throughput has increased, and our product is more reliable than ever." - Head of R&D, Medical Device Partner

At HBGX Chemical, trust is earned through expertise, authority, and transparency. We are more than a supplier; we are your partner in innovation.

With over 15 years of experience in specialty chemical synthesis, our team comprises Ph.D. chemists and engineers dedicated to photoinitiator technology. We are ISO 9001:2015 certified, and our products are trusted by leading companies in over 30 countries. Our research is frequently aligned with findings from leading academic journals in polymer science.

Quality Warranty: We guarantee that every batch of Iodonium, Bis(4-methoxyphenyl)-, iodide meets or exceeds the specifications outlined in its Certificate of Analysis.

Delivery & Logistics: Standard lead time is 7-14 business days, with expedited options available. We ship globally with robust, compliant packaging.

Customer Support: Our expert team is available 24/7 for technical inquiries, formulation advice, and order support. Contact us at sales@hbgxchemical.com.

A cationic photoinitiator is a compound that, upon absorbing UV light, generates a superacid (a Brønsted or Lewis acid). This acid then initiates a chain-reaction polymerization of specific monomers, such as epoxides and vinyl ethers. Iodonium, Bis(4-methoxyphenyl)-, iodide works by undergoing irreversible photolysis when exposed to UV energy, breaking the C-I bond to produce a highly reactive cationic radical and other species, which ultimately generate the strong acid needed to start the polymerization process.

While both are effective cationic initiators, diaryliodonium salts like this product offer several key advantages. They often exhibit greater thermal stability, which translates to a longer shelf life in formulated resins. Furthermore, their photolysis byproducts are generally considered less odorous and less likely to cause yellowing compared to some sulfonium salt byproducts, making them superior for optically clear coatings and adhesives.

This Iodonium salt has primary absorption peaks in the deep UV range, typically around 245 nm and 305 nm. While it can be used directly with UVC sources, its utility is massively expanded through photosensitization. By adding a photosensitizer (e.g., thioxanthone, anthracene derivatives), the system's spectral response can be shifted to longer, more practical wavelengths like 365 nm (Mercury lamp i-line) or even into the visible range (e.g., 405 nm LEDs), enabling the use of safer, more energy-efficient light sources.

This initiator is specifically designed for cationic polymerization. It is highly effective for ring-opening polymerization of cycloaliphatic epoxides, oxetanes, and vinyl ethers. It is generally NOT suitable for free-radical polymerization systems like acrylates and methacrylates. Its excellent performance with epoxy resins makes it a go-to choice for applications requiring high chemical resistance, excellent adhesion, and low shrinkage.

To ensure its 24-month shelf life and maintain its high reactivity, Iodonium, Bis(4-methoxyphenyl)-, iodide should be stored in a cool, dry, dark place, away from direct sunlight and heat sources. The ideal storage temperature is between 2-8°C. The container111 should be kept tightly sealed to prevent moisture absorption. It is stable at room temperature for shipping and short-term handling.

Consistency is core to our manufacturing philosophy. We achieve it through several layers of control: 1) Sourcing raw materials from qualified, audited suppliers with strict incoming QC. 2) Utilizing a highly automated and computer-controlled synthesis process to minimize human error. 3) Enforcing in-process controls at critical reaction stages. 4) Performing comprehensive final QC on every single batch with a full suite of analytical tests (HPLC, FT-IR, etc.). Every shipment includes a batch-specific Certificate of Analysis (COA) as our guarantee.

Yes, absolutely. Our high-purity (≥99%) grade is specifically engineered for such applications. The minimal impurities and the nature of the Iodonium salt's photodecomposition products result in significantly less color and yellowing compared to less pure alternatives or other classes of initiators. This makes it an excellent choice for clear protective coatings, optical adhesives, and high-clarity 3D printing resins.

Our commitment to science and expertise is grounded in the broader scientific community. For those interested in a deeper technical understanding, we recommend the following resources:

Hebei Guangxing Chemical: Integrating into the Digital Economy Ecosystem with innovative Power

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.