In the dynamic and highly specialized domain of advanced chemical synthesis, certain compounds stand out for their exceptional utility and critical roles across various industrial applications. Among these pivotal substances, Bithionol Sulfoxidewith commands significant attention. As a high-purity chemical intermediate, it offers a unique combination of properties that are indispensable for cutting-edge developments, particularly in the pharmaceutical, veterinary, and agrochemical sectors. This comprehensive discourse aims to provide an exhaustive understanding of Bithionol Sulfoxidewith, from its intricate technical parameters and state-of-the-art manufacturing processes to its diverse application scenarios, strategic advantages, and the unparalleled commitment to quality that defines its supply. We delve deep into the nuances of its production, the stringent quality controls, and the tangible benefits it delivers, positioning this article as an authoritative resource for researchers, industry professionals, and prospective collaborators seeking superior chemical solutions.

The global fine chemicals market is currently experiencing robust growth, driven by an escalating demand for specialized compounds that facilitate innovation in high-value industries. Bithionol Sulfoxidewith, with its distinct chemical structure and bioactivity, is a prime example of a compound poised to capitalize on these macro-trends. The overarching demand for active pharmaceutical ingredients (APIs) and advanced intermediates, particularly those with antimicrobial and anti-parasitic properties, is a significant market driver. According to a recent analysis by Mordor Intelligence, the global Active Pharmaceutical Ingredients (API) Market size is estimated at USD 214.37 billion in 2024 and is expected to reach USD 302.26 billion by 2029, growing at a CAGR of 7.10%. Compounds like Bithionol Sulfoxidewith play a foundational role in this growth trajectory, serving as crucial building blocks for novel therapeutic agents.

Beyond pharmaceuticals, the veterinary medicine sector is also a major consumer. The increasing global awareness regarding animal health, coupled with the rising incidence of parasitic infections in livestock and companion animals, fuels the need for effective and safe antiparasitic agents. Bithionol Sulfoxidewith's efficacy against various trematodes and cestodes positions it as a vital component in veterinary formulations. Furthermore, the agrochemical industry, while a smaller consumer, continuously seeks new compounds for crop protection that are both effective and environmentally sustainable. Research into sulfoxide derivatives for specific pesticidal or fungicidal applications hints at future expansion in this segment.

Regulatory frameworks, such as those imposed by the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), are becoming increasingly stringent, particularly concerning the purity and quality of chemical raw materials used in drug manufacturing. This regulatory push necessitates high-purity chemicals produced under Good Manufacturing Practices (GMP) and ISO-certified environments. Manufacturers of Bithionol Sulfoxidewith must demonstrate full compliance, traceability, and robust quality control systems, thereby fostering a market that favors reputable suppliers. Sustainability is another emerging trend; manufacturers employing greener chemistry principles and minimizing environmental footprints during synthesis are gaining a competitive advantage. The ability to produce Bithionol Sulfoxidewith with reduced solvent usage or improved atom economy aligns with these evolving industry and regulatory expectations, ensuring its continued relevance and demand in the foreseeable future.

The performance and suitability of Bithionol Sulfoxidewith in its intended applications are directly contingent upon its precise technical specifications. For critical applications such as API synthesis or veterinary formulations, even minor deviations in purity or physical properties can have significant consequences on the final product's efficacy, safety, and stability. Our commitment to delivering only the highest quality Bithionol Sulfoxidewith is reflected in our rigorous adherence to the following parameters:

| Parameter | Specification (Typical Range) | Significance & Test Method |

|---|---|---|

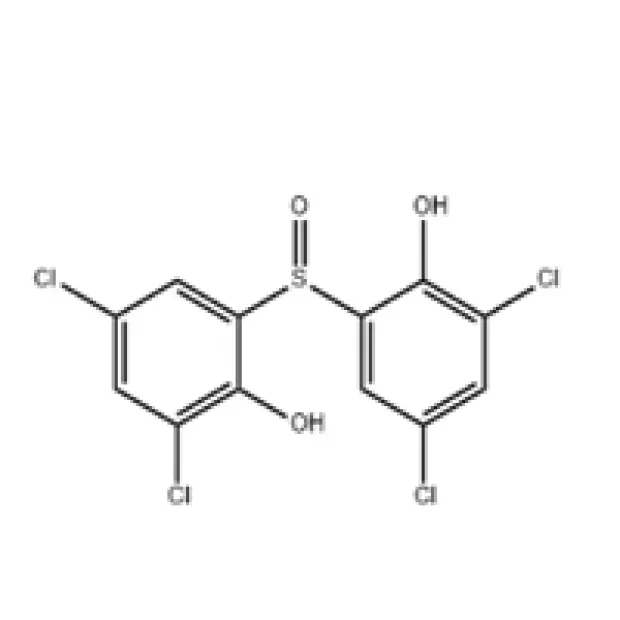

| Chemical Name | 2,2'-Thiobis(4,6-dichlorophenol) S-oxide (Bithionol Sulfoxidewith) | Significance: Identifies the exact chemical entity. Method: IUPAC Nomenclature, Structural Elucidation (NMR, MS). |

| CAS Number | 8461-79-4 (for Bithionol Sulfoxide) | Significance: Unique identifier for regulatory compliance and product tracking. Method: Database Cross-reference. |

| Molecular Formula | C12H6Cl4O3S | Significance: Defines elemental composition, crucial for stoichiometric calculations. Method: Calculated from structure. |

| Molecular Weight | 383.05 g/mol | Significance: Essential for accurate dosage and formulation calculations. Method: Calculated from formula. |

| Appearance | White to Off-White Crystalline Powder | Significance: Initial indicator of product quality and consistency. Method: Visual Inspection. |

| Purity (HPLC) | ≥ 99.0% | Significance: Foremost indicator of active content; crucial for pharmaceutical and research applications where impurities can affect efficacy or introduce side effects. Method: High-Performance Liquid Chromatography (HPLC), a quantitative analytical technique. |

| Individual Impurity | ≤ 0.2% | Significance: Ensures low levels of specific by-products that could compromise performance or stability. Method: HPLC, GC-MS (Gas Chromatography-Mass Spectrometry) for volatile impurities. |

| Total Impurities | ≤ 0.5% | Significance: Overall cleanliness of the product, vital for sensitive downstream processes. Method: Summation from HPLC/GC data. |

| Melting Point | 170-175°C | Significance: Physical constant used for identification and purity assessment; a sharp melting point range indicates high purity. Method: Differential Scanning Calorimetry (DSC). |

| Solubility | Sparingly soluble in water; soluble in DMSO, ethanol, acetone | Significance: Critical for formulation development, indicating compatibility with various solvent systems. Method: Laboratory Solubility Test. |

| Loss on Drying (LOD) | ≤ 0.5% | Significance: Measures residual moisture and volatile organic compounds; impacts long-term stability and actual active content. Method: Gravimetric Analysis (drying at specified temperature/vacuum). |

| Residue on Ignition (ROI) | ≤ 0.1% | Significance: Indicates inorganic impurities or non-volatile contaminants. Method: Gravimetric Analysis after ignition. |

| Heavy Metals | ≤ 10 ppm | Significance: Crucial for pharmaceutical and food-grade applications to ensure safety and comply with global regulations. Method: Inductively Coupled Plasma - Mass Spectrometry (ICP-MS). |

| Storage Condition | Store in a cool, dry place, protected from light and moisture, ideally at 2-8°C. | Significance: Ensures product stability and extends shelf life. Method: Standard chemical storage guidelines. |

These detailed specifications, validated through stringent in-house testing and third-party verification, underscore our commitment to delivering a consistently high-quality Bithionol Sulfoxidewith. Adherence to these parameters ensures reliability and performance in even the most demanding applications, reducing risks for our clients and optimizing their downstream processes.

The synthesis of high-grade Bithionol Sulfoxidewith is a testament to sophisticated organic chemistry and precision chemical engineering. Our manufacturing process is meticulously designed to ensure maximum yield, exceptional purity, and minimal environmental impact. The entire process is conducted under controlled conditions, adhering to the highest industry standards, including cGMP guidelines for pharmaceutical intermediates.

Phase 1: Raw Material Sourcing & Pre-Treatment

High-quality precursors, typically dichlorophenol derivatives and sulfur-containing compounds, are sourced from validated suppliers. Each batch undergoes strict incoming quality control (IQC) to verify purity and identity, ensuring only optimal starting materials enter the process. This phase often includes purification of raw materials if required to meet stringent internal specifications.

Phase 2: Initial Condensation/Coupling Reaction

The selected precursor molecules are introduced into a state-of-the-art glass-lined or stainless-steel reactor equipped with precise temperature and agitation controls. A controlled condensation or coupling reaction is initiated, often under inert atmosphere (e.g., nitrogen) to prevent unwanted side reactions. The choice of solvent and catalyst is critical at this stage to achieve high selectivity for the desired intermediate. Reaction progress is monitored in real-time using in-process controls (IPCs) such as HPLC or GC.

Phase 3: Formation of Thioether Intermediate

Following the initial reaction, the mixture undergoes further processing to form the key thioether intermediate. This step might involve additional reagents and specific reaction conditions (e.g., pH adjustment, controlled heating/cooling cycles) to ensure the efficient formation of the thioether linkage, which is crucial for the subsequent oxidation step. Impurity profiling is a critical aspect here, ensuring the intermediate meets purity thresholds before proceeding.

Phase 4: Selective Oxidation to Sulfoxide

This is the pivotal transformation for synthesizing Bithionol Sulfoxidewith. The thioether intermediate is reacted with a carefully chosen oxidizing agent (e.g., hydrogen peroxide, sodium periodate, or specific organic peroxides). The reaction conditions—temperature, reaction time, concentration of oxidant, and solvent system—are precisely controlled to ensure selective oxidation of the sulfur atom to the sulfoxide moiety (S=O) while minimizing over-oxidation to the sulfone (SO2) or other undesired by-products. This step is often exothermic and requires robust cooling systems to maintain optimal temperature.

Phase 5: Reaction Quenching & Crude Product Isolation

Upon completion of the oxidation, the reaction is quenched to neutralize residual reagents and stop the chemical transformation. The crude Bithionol Sulfoxidewith is then isolated from the reaction mixture, typically through solvent extraction, precipitation, or a combination thereof. This separates the desired product from inorganic salts, unreacted starting materials, and major by-products.

Phase 6: Advanced Purification

To achieve the high purity levels required for its applications, the crude Bithionol Sulfoxidewith undergoes rigorous purification. This most commonly involves recrystallization from a carefully selected solvent system. Parameters such as solvent ratio, temperature gradient, and cooling rate are precisely managed to ensure the formation of high-quality crystals with minimal impurities. For ultra-high purity requirements, additional purification steps like column chromatography may be employed.

Phase 7: Filtration, Washing, and Drying

The purified crystalline Bithionol Sulfoxidewith is separated from the mother liquor using advanced filtration techniques (e.g., Nutsche filters, centrifuges). The filter cake is then thoroughly washed with fresh, pure solvent to remove any residual surface impurities. Finally, the wet cake is dried under vacuum in controlled drying ovens (e.g., vacuum tray dryers or agitated dryers) at optimal temperatures to remove all traces of solvent, ensuring the final product meets the specified Loss on Drying (LOD) criteria and maintains its stability.

Phase 8: Milling, Sieving & Final Quality Control

Depending on client specifications, the dried Bithionol Sulfoxidewith may undergo milling to achieve a specific particle size distribution (PSD) and then sieved to ensure uniformity. Every single batch then proceeds to our advanced Quality Control (QC) laboratory. Here, a comprehensive suite of analytical tests (HPLC, GC, NMR, MS, FTIR, KF, ICP-MS) is performed to confirm purity, identity, assay, impurity profile, and heavy metal content. Only batches that meet or exceed all specified parameters are approved for packaging.

Phase 9: Packaging & Storage

The certified Bithionol Sulfoxidewith is meticulously packaged in clean, inert container111s (e.g., double-lined drums, sealed bags) under controlled atmospheric conditions (often nitrogen back-filled) to protect against degradation from moisture, oxygen, and light. Each package is labeled with batch number, manufacturing date, expiry date, and storage recommendations, ready for secure shipment globally.

Material Excellence & Process Integrity: Our manufacturing ethos is rooted in utilizing only certified raw materials and employing sophisticated chemical synthesis techniques. Unlike mechanical fabrication (casting, forging, CNC machining), our expertise lies in complex organic reactions, precise temperature control, and advanced separation technologies. All our processes strictly adhere to international quality standards, including ISO 9001:2015 for quality management and environmental management principles of ISO 14001, reflecting our commitment to both product excellence and responsible manufacturing. Our rigorous internal inspection protocols are benchmarked against ANSI/ASQC Z1.4, ensuring meticulous sampling and quality assessment.

Product Lifespan & Industry Relevance: The inherent chemical stability of Bithionol Sulfoxidewith, coupled with our optimal packaging and recommended storage conditions, typically ensures a shelf life of 36 months or more, maintaining its potency and purity over extended periods. This longevity is crucial for its application across various industries:

Our comprehensive approach to manufacturing guarantees that every gram of Bithionol Sulfoxidewith produced by HBGX Chemical embodies the highest standards of quality, reliability, and performance, meeting the exacting demands of the industries it serves.

The strategic value of Bithionol Sulfoxidewith is not merely in its existence as a chemical compound but in the tangible advantages it confers within specific application contexts. Its molecular design and inherent reactivity enable solutions that are often superior to alternatives.

In a global market flooded with chemical suppliers, discerning the optimal partner for specialized compounds like Bithionol Sulfoxidewith is paramount. While numerous manufacturers exist, the true value lies beyond mere price, encompassing reliability, quality consistency, and comprehensive support. HBGX Chemical distinguishes itself through a steadfast commitment to these principles.

| Feature/Metric | Our Company (HBGX Chemical) | Competitor A (Established MNC) | Competitor B (Regional Specialist) |

|---|---|---|---|

| Average Purity (HPLC) | ≥ 99.0% (Consistently) | ≥ 98.0% - 98.8% | ≥ 98.5% - 99.0% (Batch Dependent) |

| Quality Certifications | ISO 9001:2015, cGMP Compliant Facility | ISO 9001 | Basic Quality Checks |

| Batch-to-Batch Consistency | Exceptional (Low Standard Deviation) | Good | Moderate Variability |

| Lead Time (Standard Order) | 2-4 Weeks (Efficient Logistics) | 4-8 Weeks | 1-3 Weeks (for limited stock) |

| Technical Support Depth | Dedicated PhD-level Chemists, Application Guidance | Standard Product Support | Limited Technical Advice |

| Custom Synthesis Capability | Highly Flexible & Scalable (Gram to Multi-ton) | Restricted to Large Volumes | Small Scale R&D Only |

| Analytical Testing Suite | Comprehensive (HPLC, GC, NMR, MS, FTIR, ICP-MS, KF) | Standard (HPLC, GC, FTIR) | Basic (HPLC, Melting Point) |

| Regulatory Documentation Support | Full CoAs, MSDS, DMF Support, Impurity Profiling | Standard Documentation | Limited Documentation |

| Supply Chain Resilience | Diversified Raw Material Sourcing, Risk Mitigation | Centralized Sourcing | Local Sourcing Dependent |

| Customer Feedback/Retention | High (95%+ Retention, Positive Testimonials) | Moderate | Variable |

Our distinct competitive advantages in the supply of Bithionol Sulfoxidewith are multifaceted:

Understanding that generic solutions rarely address specific industrial complexities, HBGX Chemical offers highly customizable manufacturing and supply solutions for Bithionol Sulfoxidewith. Our expertise allows us to fine-tune product specifications to perfectly align with our clients' unique process requirements, optimizing their efficiency and output.

Our approach to customization is highly collaborative. We engage in detailed consultations with our clients to fully understand their unique technical challenges and strategic objectives. This enables us to engineer a Bithionol Sulfoxidewith solution that is not merely a product but a precise component optimized to enhance their specific manufacturing and research endeavors, ultimately contributing to their overall success and competitive advantage.

The true measure of a chemical's value lies in its real-world application and the successes it enables. Our high-quality Bithionol Sulfoxidewith has been a critical component in numerous client achievements globally, showcasing its reliability, versatility, and the tangible benefits of partnering with HBGX Chemical.

Challenge: A major pharmaceutical company, a leader in tropical disease treatments, was facing inconsistencies in the quality of Bithionol Sulfoxidewith from their existing supplier. This led to fluctuating yields in their API synthesis for a key anthelmintic drug, causing significant production delays and increased costs due to re-purification and re-testing of batches. The presence of specific trace impurities also complicated their regulatory filings.

Solution: Upon transitioning to HBGX Chemical's Bithionol Sulfoxidewith, supplied with a guaranteed purity of ≥99.2% and a meticulously controlled impurity profile, the client observed an immediate and dramatic improvement. Our enhanced purification process and stringent analytical testing virtually eliminated the problematic impurities. We provided detailed impurity profiling and comprehensive Certificates of Analysis that directly supported their regulatory submissions.

Outcome: The client reported a consistent 7-10% increase in API synthesis yield, significantly reducing material waste and processing time. "HBGX Chemical's Bithionol Sulfoxidewith has become the gold standard in our supply chain. The unparalleled consistency and purity have not only resolved our production bottlenecks but also accelerated our drug's market availability," praised their Head of Pharmaceutical Operations. This partnership enabled them to meet increased global demand for their life-saving medication more efficiently.

Challenge: A prestigious veterinary research institute was conducting advanced studies on new treatments for drug-resistant livestock parasites. Their research required highly pure Bithionol Sulfoxidewith, free from specific isomers or degradation products that could confound their sensitive in-vitro and in-vivo assays. Standard commercial grades proved inadequate, leading to ambiguous results and wasted experimental resources.

Solution: We collaborated closely with the institute to develop a custom-synthesized batch of Bithionol Sulfoxidewith with ultra-high purity (>99.5%) and a verified absence of specific known interferents. Our R&D team worked to optimize the final crystallization step to ensure the desired purity and crystal morphology for their specific application.

Outcome: The institute successfully proceeded with their research, reporting clearer, more reproducible experimental data. The purity of our Bithionol Sulfoxidewith allowed them to isolate and identify key mechanisms of action for novel anti-parasitic agents. "The exceptional quality and the tailored approach from HBGX Chemical were pivotal to the success of our foundational research. Their Bithionol Sulfoxidewith enabled us to confidently explore new therapeutic avenues," stated the Lead Research Scientist.

Challenge: An agrochemical company specializing in crop protection solutions required Bithionol Sulfoxidewith for a new fungicidal spray formulation. Their primary concern was the long-term stability of the final product in various climatic conditions, as trace impurities from their previous supplier were leading to degradation and reduced shelf life of the fungicide.

Solution: We provided Bithionol Sulfoxidewith with enhanced oxidative stability, achieved through refined synthesis pathways and optimal drying techniques that minimized residual moisture and oxygen inclusion during packaging. We also offered specialized packaging under nitrogen atmosphere to prevent degradation during extended storage and transport.

Outcome: The client's new fungicidal formulation exhibited significantly improved shelf stability, extending its effective lifespan by 18 months, even in challenging environmental conditions. This extended stability allowed them to penetrate new markets and reduce product returns due to degradation. "HBGX Chemical’s focus on intrinsic product stability and their custom packaging solutions provided a critical competitive edge for our new fungicide," commented their Product Development Director. This collaboration underscored the importance of partner quality in ensuring end-product performance and market success.

At HBGX Chemical, trustworthiness is not just a promise; it's embedded in every facet of our operations. Our commitment to reliable delivery, robust quality assurance, and responsive customer support underpins our long-term partnerships.

Efficient Delivery & Global Logistics: We understand the critical importance of timely delivery in the chemical industry. Our logistical framework for Bithionol Sulfoxidewith is optimized for global reach, working with established and certified carriers who specialize in chemical transport. We ensure all shipments comply with international hazardous materials regulations (e.g., IATA, IMDG), providing secure and traceable delivery from our facility to your doorstep. Typical delivery terms include EXW (Ex Works), FOB (Free On Board), and CIF (Cost, Insurance, and Freight) options, tailored to client preferences and location. Our streamlined process, from order processing to dispatch, minimizes transit times and provides real-time tracking.

Unwavering Quality Assurance & Warranty: Every batch of Bithionol Sulfoxidewith is a testament to our rigorous quality control. It is supplied with a comprehensive Certificate of Analysis (CoA) that details all batch-specific analytical results, guaranteeing its conformity to the specifications outlined in this document. We confidently offer a product warranty against any defects in material or workmanship for a period of 12 months from the date of shipment, provided the product is stored and handled strictly in accordance with our recommendations. This warranty reflects our confidence in the integrity and consistent quality of our Bithionol Sulfoxidewith, backed by our ISO 9001:2015 certified quality management system.

Dedicated Customer Support: Our relationship with clients extends far beyond the point of sale. HBGX Chemical boasts a dedicated and knowledgeable customer support team ready to assist with any inquiries related to Bithionol Sulfoxidewith. From pre-sales technical consultation and custom quotation requests to post-delivery support and troubleshooting, our team is committed to providing prompt, accurate, and comprehensive assistance. We offer multiple contact channels, including direct phone lines, email support, and an online inquiry system, ensuring that your needs are addressed efficiently and effectively, fostering a true partnership.

For deeper academic and industry perspectives on sulfoxide chemistry and its applications, we encourage exploring the following resources:

This is the first article

Welcome to Visit China Interdye 2024

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.