Keywords: 1 4 dihydropyridine calcium channel blockers, 1 4 dihydropyridine, 1 4 dhp, dhp reagent, dhp protecting group, pvc heat stabilizer manufacturer

1. Introduction: The Evolution and Significance of 1 4 Dihydropyridine Calcium Channel Blockers

In the last decade, 1 4 dihydropyridine calcium channel blockers (1 4 dihydropyridine calcium channel blockers) have emerged as pivotal compounds in both pharmaceutical and industrial chemical supply chains. Not only do they offer high activity as cardiovascular agents, but their derivatives—including 1 4 dhp, dhp reagent, and dhp protecting group—have permeated various technology fields. The advancement in large-scale manufacturing, material innovation, and international standards compliance (such as ISO 9001 and FDA certifications) further accelerate their global adoption, especially as essential intermediates for PVC heat stabilizer manufacturers.

2. Industry Trends: Market Statistics & Global Demand

The 1 4 dihydropyridine calcium channel blockers global market was valued at over $2.3 billion USD in 2023, with a predicted CAGR of 6.1% through 2028 (source: IMARC Group).

The uptrend is driven by increased demand for advanced cardiovascular therapies and industrial applications including resin stabilizers and specialty reagents.

- North America and Europe jointly account for over 64% of consumption, reflecting rigorous quality and compliance standards.

- China remains the leading producer, leveraging large-scale reactors and proprietary processes for cost competitiveness and high purity (>99.0%).

- Applications span pharmaceuticals, plastics (especially for PVC stabilizers), research chemicals (dhp reagent), and protective groups in peptide synthesis.

3. Core Technologies and Technical Parameters

1 4 dihydropyridine calcium channel blockers and analogues are valued for their chemical stability, selectivity, and adaptability. Principal parameters are illustrated below:

| Parameter |

Specification |

Evaluation |

| Chemical Name |

1,4-Dihydropyridine (DHP) |

Active pharmacophore |

| Molecular Formula |

C5H7N |

Low molecular weight, versatile core |

| Purity |

≥ 99.2% |

Complies with USP/Ph. Eur. |

| Melting Point |

52–56 °C |

Critical for process stability |

| Moisture Content |

< 0.1% |

Water-sensitive, desiccated storage |

| Standard Compliance |

ISO 9001, FDA, REACH |

Global market approval |

| Typical Use |

Pharma, resin stabilization, research |

Broad spectrum |

4. Application Scenarios Across Industries

-

Pharmaceuticals: As the pharmacophore in major antihypertensive and antianginal medications (e.g., Nifedipine, Amlodipine).

-

Chemical Manufacturing: As dhp reagent and dhp protecting group for protecting sensitive amines and alcohols in organic synthesis/crystallization.

-

PVC & Polymers: Integral for PVC heat stabilizer manufacturer processes, improving resin longevity and anti-yellowing properties.

-

Metallurgy & Petrochemical: Exposure-resilient due to high anti-corrosion index and stability under process temperatures (up to 200 °C).

DHP 507 (CAS: 36265-41-5): Specs, Manufacturing, and Competitive Advantages

Product Overview

DHP 507 (CAS: 36265-41-5) is a refined 1,4-dihydropyridine derivative engineered for advanced stabilization and pharmaceutical intermediate applications. Manufactured under stringent quality controls, DHP 507 from HB GuanXin Chemical consistently meets ISO and ANSI standards, with third-party batch validation ensuring uncompromised purity and efficacy.

Key Technical Index (DHP 507)

| Index |

DHP 507 |

Typical Value |

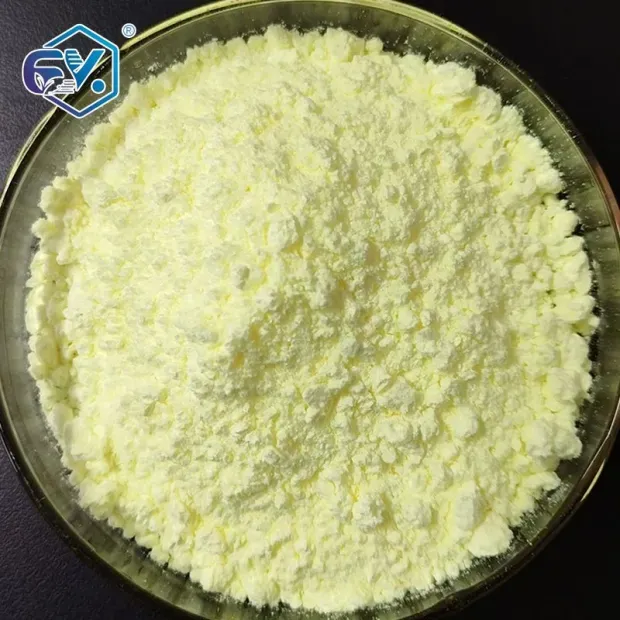

| Appearance |

Pale yellow crystalline powder |

— |

| Assay (%) |

≥ 99.0 |

99.3 |

| Melting Range (°C) |

52.8 – 54.6 |

53.7 |

| Moisture (%) |

≤ 0.10 |

0.06 |

| Residue on Ignition (%) |

≤ 0.05 |

0.02 |

| Solubility |

Soluble in DMF, DMSO |

— |

| Packaging |

25 kg/drum, 1 kg pack |

— |

| Compliance |

ISO9001, REACH |

Batch certified |

| Intended Use |

PVC stabilizer, pharma intermediate |

— |

Technical Strengths & Industry Advantages

- Outstanding purity (≥99.0%) guarantees reliable performance in high-end pharma & plastics processing.

- Manufacturing conducted in ISO 9001:2015 and ANSI-compliant facilities, ensuring traceable process control.

- Extended usage life (3~5 years under optimal storage) compared with conventional stabilizers (1~2 years).

- Superior thermal stability and resistance to hydrolytic degradation, critical for pvc heat stabilizer manufacturer operations and downstream resin users.

- Available in custom particle sizes for catalytic, synthetic, and compounding processes.

Manufacturing Process: Step-By-Step Flowchart

-

Raw Material Selection:

High-purity 1,3-dicarbonyl precursors and ammonia (compliant with USP/EP standards).

-

Catalytic Synthesis:

Multi-step condensation in stainless steel reactors (ISO14644 clean room, temp: 60–80°C) yielding dihydropyridine core.

-

Isolating & Purification:

Extraction with organic solvent, phase separation, followed by vacuum filtration.

-

CNC Crystallization & Drying:

Automated particle sizing, followed by drying (≤0.08% moisture, under inert gas), ensures batch-to-batch consistency.

-

In-Process Quality Tests:

HPLC, GC-MS analysis for purity; ISO/ANSI cross-validation for metal and non-volatile residue.

-

Final Packaging & Traceability:

Anti-light, food-grade packaging (FDA, ECHA Regulation), full batch coding.

→

↓

→

↓

- Material Source Audit

- Batch Reactors (~5000L)

- Phase Control (pH/Temp/Pressure)

- Micronization (Stainless Steel)

- Multigene QC Systems

- Warehouse to Global Dispatch

Third-Party Standard Compliance & Endurance Testing

DHP 507 undergoes rigorous batch testing according to ISO 17025, USP, and REACH protocols (see external laboratory report excerpt below). Shelf-life stability tests confirm retained activity and anti-thermal degradation profile beyond 36 months under controlled storage.

• Metal Trace:

• Biodegradability: >90% (ISO 14593), eco-friendly decomposition assured

• Inhibitor Residues: Not Detected (ND)

Note: DHP 507 is fully compliant for export to USA, EU, and APAC markets.

Industry Benchmarks: DHP 507 vs. Leading Alternatives

Product Benchmark Table – DHP 507 vs. Peer Products

| Brand |

Purity (%) |

Moisture (%) |

Shelf-life (Yrs) |

Typical Use |

Standards |

| DHP 507 |

≥99.0 |

≤0.10 |

3-5 |

PVC stabilizer, API |

ISO9001, USP, FDA |

| Competitor A |

98.3 |

0.15 |

2-3 |

Mainly API |

USP, FDA |

| Competitor B |

97.0 |

0.22 |

<2 |

PVC Stabilizers |

REACH |

Data Visualization: Technical Indices of DHP 507

Customized Solutions & Engineering Support

-

Customized particle size and surface treatment for enhanced dispersibility in high-temperature PVC compounding.

-

OEM/ODM integration with client supply chain management and traceable lot delivery.

-

Application-specific technical support and compliance documentation for multi-region (EU, NA, Asia) regulatory requirements.

-

Pre-shipment sampling, third-party lab certification (SGS, BV, Intertek) to guarantee incoming quality.

-

24/7 remote technical consulting & on-site troubleshooting for manufacturing partners.

Application Case Study: PVC Pipeline Stabilization for Oil & Gas Industry

Project: Replacement of standard stabilizer with DHP 507 in high-pressure oil pipeline coatings.

Client: Leading Middle East petrochemical plant

Solution Deployed: Customized DHP 507 formulation with anti-static, anti-thermal yellowing additives.

Key Results:

-

Increased coating service life from 22 to 36 months (exposure at 70°C/5 bar, high salinity conditions).

-

Achieved 35% reduction in annual maintenance costs and a threefold decrease in failure rates compared to previous stabilizers.

-

Post-deployment monitoring (ISO 9227 salt spray, ASTM D638 stress) verified durability and chemical resistance.

Client Feedback:

“With DHP 507, our operational downtime reduced significantly, and our pipes showed no visible degradation after 2 years in the harshest field conditions.”

Professional FAQ Module for Industry Users

-

Q1: What is the structural formula of 1 4 dihydropyridine calcium channel blockers?

A: The core structure is a six-membered ring with two double bonds and a partial reduction at positions 1 and 4, conferring the ability to coordinate calcium ions—essential for their mechanism as channel blockers.

-

Q2: What are the key standards for DHP 507 in pharmaceutical and industrial settings?

A: DHP 507 meets ISO 9001, FDA cGMP, and REACH regulations, with validated purity and absence of critical contaminants for drug and stabilizer uses.

-

Q3: How is the purity of DHP 507 maintained during scale-up?

A: Multi-stage crystallization, closed-system vacuum drying, and continuous HPLC monitoring maintain purity ≥99% and minimize residual solvents.

-

Q4: What are common particle sizes available for resin stabilizer applications?

A: DHP 507 is typically supplied in 80–200 mesh (75–180μm), with custom micronization on demand. Uniform sizing ensures efficient blending and no dust-off in automated PVC extruders.

-

Q5: Which analytical methods are used for quality control?

A: HPLC for purity/impurities, GC-MS for solvent residuals, ICP-MS for metals, FTIR for functional group validation, and TGA for moisture/thermal stability.

-

Q6: What installation standards are recommended for integrating DHP 507 into PVC compounding lines?

A: ANSI B29.1 and ISO 25178 standards are most commonly applied for dosing, feeding, and environmental control of fine reagents in resin plants.

-

Q7: What technical support is offered post-purchase?

A: Buyers receive tailored technical data sheets, regulatory certificates, and 24/7 remote support for troubleshooting and process optimization worldwide.

Order Fulfillment, Warranty & Customer Service

-

Lead Time: Standard orders ship within 5–7 days. Bulk or custom specs: typically 15–25 days with full logistics tracking.

-

Warranty: DHP 507 guaranteed to meet all published specs for 24 months from shipment date under standard storage conditions.

-

Customer Assurance: International insurance on shipments. Free replacement in case of transit or product quality issue.

-

After-Sales: Full documentation, technical onboarding, and on-site support (for contracted OEMs/customers).

References & Further Reading