HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. has established itself as a global leader in the production of high-purity Pharma-Zwischenprodukte that meet the most stringent quality standards in the pharmaceutical industry. Our specialized APIs and intermediates with ultra-low sulfate ash content represent our commitment to excellence in chemical manufacturing. As one of the foremost pharma intermediates manufacturers, we combine advanced technology with rigorous quality control to deliver products that pharmaceutical companies can trust for their critical formulations. This article explores our technical capabilities, quality systems, and corporate philosophy that have made us a preferred partner for pharmaceutical ingredient supply.

HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. Sets New Standards For Pharma Intermediates Purity

- Our manufacturing expertise allows HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. to produce Pharma-Zwischenprodukte with exceptional purity levels, including the remarkable 0.2% sulfate ash specification.

- As leading pharma intermediates manufacturers, we've developed proprietary purification processes that remove impurities while maintaining high yields of APIs and intermediates.

- Our state-of-the-art facilities incorporate advanced crystallization and filtration technologies to achieve these stringent quality parameters.

- The low sulfate ash content in our products ensures better compatibility with sensitive pharmaceutical formulations and reduces potential side reactions.

- This commitment to purity has earned us the trust of major pharmaceutical companies worldwide.

Advanced Manufacturing Processes Deliver Superior APIs And Intermediates

- HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. has invested significantly in developing specialized production methods for high-quality APIs and intermediates.

- Our Pharma-Zwischenproduktebenefit from multi-stage purification processes that consistently achieve the 0.2% sulfate ash standard.

- As experienced pharma intermediates manufacturers, we understand that consistency is as important as purity, which is why we've implemented rigorous process controls throughout our manufacturing operations.

- Our technical team continuously optimizes reaction parameters and work-up procedures to enhance both the quality and efficiency of our APIs and intermediates

- This systematic approach ensures reliable supply of materials that meet exacting pharmaceutical requirements.

Quality Systems Underpin Our Pharma Intermediates Manufacturing

The reputation of HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. as reliable pharma intermediates manufacturers stems from our uncompromising quality assurance systems. Every batch of our Pharma-Zwischenprodukte undergoes comprehensive testing to verify the 0.2% sulfate ash specification and other critical quality parameters. Our APIs and intermediates are analyzed using advanced chromatographic and spectroscopic techniques in fully equipped quality control laboratories. We maintain complete documentation trails and provide detailed certificates of analysis with all shipments. This thorough approach to quality control has made us the partner of choice for pharmaceutical companies that cannot compromise on ingredient purity and consistency.

|

Artikel

|

Details

|

|

CAS

|

36265-41-5

|

|

Name

|

Didodecyl,4-dihydro-2,6-dimethylpyridine-3,5-dicarboxylate

|

|

EINECS NO

|

252-939-2

|

|

SYNONYM

|

Multistab DHP 507 / Didodecyl-1,4-dihydro-2,6-dimethylpyridin-3,5-dicarboxylat / Didodecyl-1,4-dihydro-2,6-dimethylpyridin-3,5-dicarboxylat

|

|

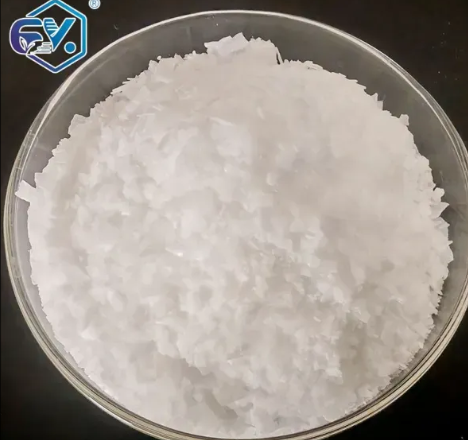

Aussehen

|

Hellgelbgrünes Pulver

|

|

Assay

|

97,0 %Min

|

|

Schmelzpunkt

|

93.0-96.0°C

|

|

Loss on drying

|

0,5 % Max

|

|

Sulfate ash

|

0,2 %Max

|

|

Methenamine content

|

0,25 %Max

|

|

The number of black spots

|

5Max

|

|

The number of black dots over 0.5mm

|

3Max

|

Sustainable Practices Guide Our Pharma Intermediates Production

HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. integrates environmental responsibility into all aspects of our Pharma-Zwischenprodukte manufacturing. Our processes for producing APIs and intermediates incorporate green chemistry principles, solvent recovery systems, and waste minimization strategies. As forward-thinking pharma intermediates manufacturers, we've developed energy-efficient production methods that reduce our environmental footprint while maintaining product quality. The low sulfate ash content in our products reflects not just purity achievements but also our commitment to sustainable manufacturing practices that benefit both our customers and the environment.

Pharma Intermediates FAQs

What Analytical Methods Verify Your Pharma Intermediates Purity

HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. employs multiple advanced techniques to confirm the 0.2% sulfate ash specification in our Pharma-Zwischenprodukte. Our quality control laboratories utilize HPLC, GC-MS, ICP-OES, and other sophisticated methods to analyze APIs and intermediates. As leading pharma intermediates manufacturers, we provide comprehensive certificates of analysis documenting all critical quality parameters.

How Does Your Company Ensure Consistent APIs And Intermediates Quality

Our quality assurance system for APIs and intermediates includes rigorous process validation, in-process testing, and final product verification. HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. implements statistical process control methods to maintain batch-to-batch consistency in our Pharma-Zwischenprodukte production. The 0.2% sulfate ash specification is strictly monitored through multiple checkpoints.

What Technical Support Do You Provide With Pharma Intermediates

Beyond supplying high-quality Pharma-Zwischenprodukte, HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. offers comprehensive technical support for our APIs and intermediates. Our experienced chemists can provide guidance on storage conditions, handling recommendations, and compatibility information. As established pharma intermediates manufacturers, we understand the importance of application support in pharmaceutical manufacturing.

Can You Develop Custom Pharma Intermediates Formulations

HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. regularly develops customized Pharma-Zwischenprodukte to meet specific customer requirements. Our R&D team can adjust synthesis and purification processes to achieve particular specifications in APIs and intermediates, including specialized purity profiles beyond the standard 0.2% sulfate ash level.

How Does Your Manufacturing Process Of Pharma Intermediates Address Environmental Concerns

Our production of Pharma-Zwischenprodukte incorporates multiple sustainability initiatives, including solvent recovery, waste minimization, and energy efficiency measures. HEBEI GUANGXING CHEMICAL INDUSTRY CO., LTD. continuously evaluates greener alternatives for manufacturing APIs and intermediates without compromising quality. The low sulfate ash content in our products reflects our commitment to clean production technologies.