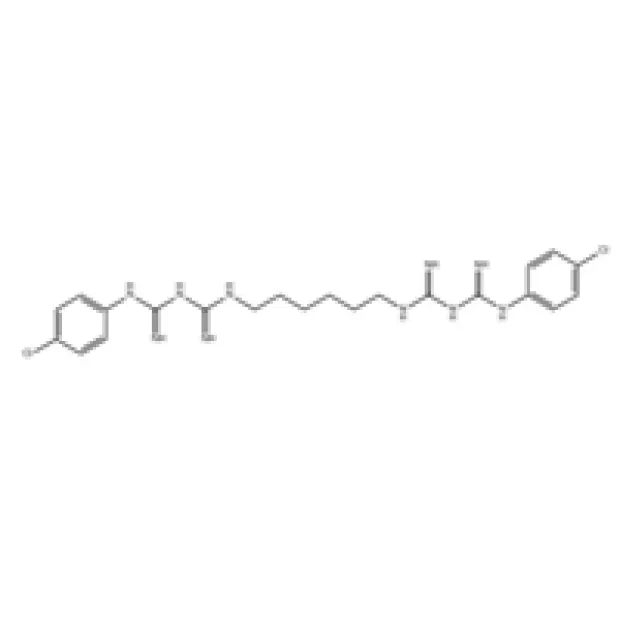

In the evolving landscape of healthcare and industrial sanitation, the demand for highly effective antimicrobial agents is paramount. Chlorhexidine stands as a cornerstone compound, widely recognized for its potent, broad-spectrum antiseptic properties. As a cationic biguanide, it exhibits remarkable efficacy against a wide range of gram-positive and gram-negative bacteria, fungi, and some viruses, making it indispensable in diverse applications from clinical settings to consumer products. Recent industry trends highlight a continuous growth in its market, driven by increasing awareness of hygiene, rising rates of healthcare-associated infections (HAIs), and its proven track record in infection control. Manufacturers are focusing on advanced purification techniques and novel formulations to enhance stability and reduce irritation, addressing specific market needs for higher purity grades and specialized delivery systems.

The versatility of Chlorhexidine is a key factor in its expanding utility. Its mechanism of action involves disrupting the bacterial cell membrane, leading to leakage of intracellular components and eventual cell death, a process that minimizes the development of antimicrobial resistance compared to some traditional antibiotics. This inherent resistance profile makes it a preferred choice for long-term use in preventive and therapeutic applications. Furthermore, its substantive binding to skin and mucous membranes provides a persistent antimicrobial effect, which is crucial in surgical preparation and wound management. This enduring efficacy, combined with a favorable safety profile when used as directed, positions Chlorhexidine as a critical chemical compound influencing public health and industrial hygiene standards globally.

The production of high-grade Chlorhexidine involves a sophisticated chemical synthesis process, meticulously controlled to ensure exceptional purity and efficacy. The primary raw materials typically include hexamethylenediamine and dicyandiamide, which undergo a series of precise reactions. The manufacturing process begins with the condensation reaction, often carried out under controlled temperature and pressure, to form an intermediate compound. This initial synthesis step is critical for defining the basic molecular structure of Chlorhexidine. Subsequent stages involve purification, which is paramount for pharmaceutical and medical-grade applications.

Figure 1: Conceptual illustration of a Chlorhexidine manufacturing facility emphasizing purification.

Following the initial synthesis, the crude product undergoes rigorous purification steps. This often includes solvent extraction, filtration, and multiple recrystallization stages to remove impurities and unwanted byproducts. For instance, a multi-stage crystallization process ensures the desired polymorph and crystal habit, critical for product stability and solubility. Drying processes are then carefully managed to achieve optimal moisture content, typically using vacuum or spray drying techniques. Quality control is integrated throughout the entire manufacturing chain. Each batch is subjected to stringent检测标准 (detection standards) such as High-Performance Liquid Chromatography (HPLC) for assay and impurity profiling, Gas Chromatography (GC) for residual solvents, and titration for accurate concentration determination. Compliance with international standards like USP (United States Pharmacopeia), BP (British Pharmacopoeia), and EP (European Pharmacopoeia) is strictly adhered to, ensuring consistency and global usability.

The applicable industries for high-purity Chlorhexidine span healthcare, veterinary medicine, personal care, and industrial sanitation. In healthcare, it is vital for surgical scrubs, oral rinses, wound dressings, and catheter site care, significantly reducing infection rates. In the food and beverage sector, its non-corrosive and effective biocidal properties make it suitable for surface disinfection. Its chemical stability contributes to a long service life, typically with a shelf life of 2-3 years under proper storage conditions, ensuring product integrity for diverse applications. The inherent advantages in typical application scenarios, such as its persistent antimicrobial action on skin and surfaces, contribute to substantial benefits in infection prevention and overall hygiene efficiency.

The efficacy of Chlorhexidine is underscored by its precise technical parameters and performance metrics. These specifications are critical for formulators and end-users to ensure optimal application and desired antimicrobial outcomes. Different forms of Chlorhexidine, such as Chlorhexidine Gluconate (CHG), Chlorhexidine Acetate, and Chlorhexidine Hydrochloride, offer varying solubility profiles and stability characteristics suitable for specific formulations. The choice of form depends heavily on the intended application, whether it's an aqueous solution for skin antisepsis or a powder for specific pharmaceutical preparations.

| Parameter | Specification | Standard/Method |

|---|---|---|

| Assay (Chlorhexidine Gluconate) | 19.0% - 21.0% w/v | USP / BP / EP |

| Appearance | Clear, almost colorless liquid | Visual Inspection |

| Specific Gravity (20°C) | 1.060 - 1.070 | Pycnometer Method |

| pH (1% aqueous solution) | 5.5 - 7.0 | Potentiometric |

| Chloride | Max 0.05% | Titration |

| Related Substances (EP method) | Individual max 0.5%, Total max 1.0% | HPLC |

| Bacterial Endotoxins | < 0.25 EU/ml | LAL Test |

Minimum Inhibitory Concentration (MIC) values demonstrate the potency of Chlorhexidine against various microorganisms, typically ranging from 0.5 to 8 µg/mL for susceptible bacteria. Its rapid bactericidal action, usually within 30 seconds to 2 minutes of contact, is a critical advantage in emergency and surgical settings. The extended residual activity, where it continues to kill microorganisms for several hours after application, differentiates it from alcohol-based disinfectants. This substantive property is particularly beneficial in pre-operative skin preparation, where sustained microbial reduction is essential for preventing surgical site infections. Choosing a supplier that adheres strictly to these parameters is vital for product consistency and therapeutic reliability.

The wide-ranging applications of Chlorhexidine underscore its critical role across numerous sectors. In the medical field, it is indispensable for pre-operative skin antisepsis, effectively reducing surgical site infections (SSIs). Hospitals extensively use Chlorhexidine-based washes for patient bathing prior to surgery, and for hand hygiene among medical personnel. Dental professionals rely on Chlorhexidine mouthrinses for treating gingivitis and preventing dental plaque formation due to its strong anti-plaque and anti-gingivitis properties. Beyond healthcare, it's integrated into veterinary medicine for animal wound care and surgical prep, and in consumer products like antiseptic wipes, contact lens solutions, and cosmetic preservatives.

Consider a major healthcare network in the Northeast United States. Facing persistent challenges with central line-associated bloodstream infections (CLABSIs), they implemented a comprehensive protocol including daily bathing with 2% Chlorhexidine gluconate wash for all ICU patients and Chlorhexidine-impregnated dressings for central venous catheters. Over a two-year period, this intervention led to a remarkable 70% reduction in CLABSIs, translating into significant cost savings from reduced hospital stays and improved patient outcomes. This case exemplifies the tangible benefits of incorporating high-quality Chlorhexidine products into infection prevention strategies. Another example includes a large-scale food processing plant that adopted a Chlorhexidine-based surface disinfectant. This shift resulted in a measurable reduction in bacterial counts on critical contact surfaces, enhancing food safety compliance and minimizing the risk of product contamination. These real-world applications demonstrate the robust efficacy and economic benefits of utilizing premium-grade Chlorhexidine.

Selecting the right supplier for Chlorhexidine is a strategic decision for businesses, impacting product quality, supply chain reliability, and cost-efficiency. Key factors to consider when comparing manufacturers include their adherence to international quality standards (e.g., ISO 9001, cGMP), the purity and consistency of their product, their production capacity, and their ability to offer technical support and custom solutions. While many manufacturers produce Chlorhexidine, not all offer the same level of purity or regulatory compliance essential for sensitive applications such as pharmaceuticals or medical devices.

| Feature | Supplier A (Premium) | Supplier B (Standard) | Supplier C (Budget) |

|---|---|---|---|

| Purity (Assay) | >99.5% (EP/USP Grade) | >98.0% (Industrial Grade) | >95.0% (General Use) |

| Regulatory Certifications | ISO 9001, GMP, FDA DMF | ISO 9001 | None specified/Limited |

| Lead Time (Standard Order) | 2-3 Weeks | 3-5 Weeks | 4-6 Weeks |

| Custom Formulation Support | Extensive R&D, Technical team | Limited consultation | Minimal/None |

| After-Sales Support | Dedicated Account Manager, 24/7 | Standard business hours | Email support only |

Many B2B clients require more than just off-the-shelf products. Custom solutions for Chlorhexidine can include specific concentrations, specialized packaging, or tailored forms (e.g., micronized powder for specific drug delivery systems, or different salt forms for solubility). A reputable manufacturer will possess the R&D capabilities and production flexibility to meet these bespoke requirements, providing comprehensive technical data and stability studies. Our company, with years of dedicated service in the chemical industry, offers such robust customization, backed by ISO-certified processes and a commitment to quality. This ensures that clients receive precisely the product needed for their unique applications, optimizing their end-product performance and market competitiveness.

Chlorhexidine should be stored in tightly closed container111s, protected from light, and at room temperature (typically between 15°C and 30°C). Freezing or excessive heat can affect its stability and efficacy. Always refer to the product's Certificate of Analysis and label for specific storage recommendations.

For standard bulk orders, our typical delivery cycle is 2-4 weeks, depending on the volume and specific product form (e.g., solution or powder). For custom orders or very large quantities, the lead time may extend to 4-6 weeks to accommodate specialized production runs and rigorous quality checks. We work closely with clients to manage logistics and ensure timely delivery.

We adhere to strict quality management systems, including ISO 9001 certification and compliance with cGMP guidelines. Each batch of Chlorhexidine undergoes comprehensive quality control testing and comes with a Certificate of Analysis (CoA) verifying its purity and specifications. Our products are guaranteed to meet or exceed stated pharmacopoeial standards (USP, BP, EP) for a period of 12-24 months from the date of manufacture, provided proper storage conditions are maintained. Our technical support team is available to address any product-related queries or issues promptly.

This is the first article

Methyltin Stabilizer HBGX Trusted Partner Reputation

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.