In the realm of advanced chemical synthesis, cas no 96 31 1, known chemically as 1,3-Dimethylurea (DMU), stands as a pivotal intermediate. Our 1,3-Dimethylurea is supplied in convenient flake form, ensuring optimal handling and precise dosing for a wide array of industrial applications. This compound's unique molecular structure lends itself to diverse synthetic pathways, making it indispensable across sectors ranging from pharmaceuticals and agrochemicals to specialty polymers and resins. The market for high-purity DMU is driven by stringent quality requirements and the continuous innovation in downstream applications, demanding consistent quality and reliable supply from manufacturers.

As global industries evolve, the demand for high-performance chemical building blocks like 96 31 1 continues to grow. Key industry trends highlight a rising need for compounds that facilitate greener chemical processes, enhance product efficacy, and contribute to sustainable manufacturing. For example, its role in certain purification processes, or as a precursor for specific materials, subtly connects to concepts explored in the context of adsorbate and adsorbent systems, where precise chemical interactions are paramount for effective separation or catalytic performance. Our commitment to quality ensures that our 1,3-Dimethylurea (Flakes) meets the exacting standards required by today's leading innovators.

The production of high-purity 1,3-Dimethylurea (Flakes) involves a meticulously controlled multi-stage synthesis and purification process. Typically, this begins with the reaction of methylamine with phosgene or a phosgene equivalent, followed by a series of precise chemical transformations to yield 1,3-Dimethylurea. Our proprietary manufacturing process emphasizes raw material purity, optimized reaction conditions, and stringent post-synthesis purification techniques to achieve the desired assay and minimize impurities. This ensures our product's stability and reactivity for sensitive applications.

Post-synthesis, the DMU solution undergoes a specialized crystallization and flaking process. This involves controlled cooling and mechanical handling to form the uniform flakes, which are ideal for ease of handling, reduced dusting, and improved dissolution rates compared to powders. Every batch is subjected to rigorous quality control checks against internal and external standards. Our facility adheres to ISO 9001 quality management systems, ensuring traceability and consistent product quality. We conduct comprehensive analytical testing, including Gas Chromatography (GC) for purity, Karl Fischer titration for moisture content, and melting point analysis, to confirm that each lot of 96 31 1 meets precise specifications. This dedication to quality translates into a reliable product with exceptional service life when stored under recommended conditions.

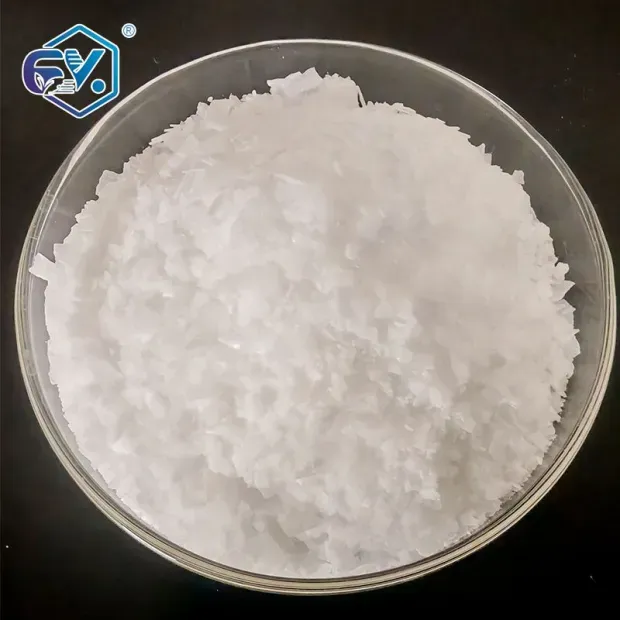

Precision-manufactured 1,3-Dimethylurea (Flakes) ready for diverse industrial applications.

The robust manufacturing controls and adherence to international inspection standards, such as those recommended by ANSI and ISO for chemical purity and handling, are critical for maintaining product integrity. While traditional terms like casting or forging are not directly applicable to chemical synthesis, our analogous commitment to process control ensures the structural and chemical integrity of the flakes, making them suitable for demanding sectors such as petrochemical intermediaries, metallurgy auxiliaries, and even advanced water treatment formulations where precise chemical dosing and stability are paramount. The superior purity and consistent physical form contribute to operational efficiency and reduced waste in downstream processes, aligning with principles of energy saving and material optimization.

Understanding the precise technical parameters of cas no 96 31 1 is crucial for its effective integration into industrial processes. Our 1,3-Dimethylurea (Flakes) is characterized by consistent purity and well-defined physical properties, ensuring reliable performance in various applications. The table below provides key specifications based on our rigorous quality control protocols and industry standards. These parameters are critical for R&D departments and production engineers to formulate new products and optimize existing processes, particularly in demanding fields like pharma research and specialty chemical synthesis.

| Parameter | Specification |

|---|---|

| CAS Number | 96-31-1 |

| Chemical Name | 1,3-Dimethylurea |

| Molecular Formula | C3H8N2O |

| Molecular Weight | 88.11 g/mol |

| Appearance | White Flakes |

| Purity (GC) | ≥ 99.5% |

| Melting Point | 100-104 °C |

| Moisture Content | ≤ 0.1% |

| Solubility | Soluble in Water, Ethanol, Chloroform |

| Ash Content | ≤ 0.05% |

These detailed specifications underscore our commitment to delivering a high-quality product. The low impurity profile and consistent physical form are critical for applications where purity directly impacts reaction yield or final product quality, such as in the synthesis of sensitive active pharmaceutical ingredients (APIs). Our product’s consistent performance is a testament to our robust quality assurance processes and extensive experience in the field of fine chemical manufacturing. This data provides the transparency and reliability necessary for B2B procurement and technical validation.

1,3-Dimethylurea (96 31 1) serves as a versatile building block in numerous industrial syntheses due to its reactive nitrogen and carbonyl groups. A primary application is in the pharmaceutical industry, where it acts as a crucial intermediate for various drugs, including specific antineoplastic agents and psychotropic medications. Its high purity and consistent reactivity are paramount in pharma research and manufacturing, where even trace impurities can compromise drug safety and efficacy. Additionally, DMU finds significant use in the production of agrochemicals, such as herbicides and fungicides, contributing to the development of more effective and environmentally compliant crop protection solutions.

Beyond pharmaceuticals and agrochemicals, cas no 96 31 1 is employed in the synthesis of specialty resins and polymers, textile auxiliaries, and as a raw material for various fine chemicals. Its contribution to polymer chemistry can involve modification of polymer chains or as a monomer in specific polymerizations, impacting properties like thermal stability and flame retardancy. In certain advanced materials, DMU derivatives can play a role in creating structured porous materials, indirectly relating to the principles of an adsorbent or materials with specific surface properties critical for selective separation. Our product's flake form offers distinct handling advantages, reducing dust and improving flowability in automated dosing systems, which translates into enhanced operational safety and efficiency in high-volume production environments.

The technical advantages of choosing our 1,3-Dimethylurea are rooted in its consistent quality and the precision of its manufacturing. High purity translates to cleaner reactions, higher yields, and reduced downstream purification costs for our clients. For instance, in complex multi-step organic syntheses, the low impurity profile of our DMU minimizes side reactions, leading to purer intermediates and final products. This not only streamlines the manufacturing process but also enhances the overall sustainability by reducing waste byproducts. Our long-standing expertise in chemical production ensures a product that consistently performs, contributing to the competitiveness of our partners.

Recognizing the diverse and evolving needs of industrial clients, we offer flexible customization options for cas no 96 31 1. While our standard 1,3-Dimethylurea (Flakes) meets a broad spectrum of applications, we understand that specific projects, especially in cutting-edge pharma research or novel material development, may require tailored specifications. This could include variations in particle size distribution, moisture content, or even specific impurity profiles for highly specialized syntheses. Our technical team works closely with clients to define and achieve these bespoke requirements, leveraging our advanced production capabilities and analytical expertise.

Our approach goes beyond simply supplying chemicals; we aim to form long-term strategic partnerships. For complex projects involving adsorbate and adsorbent applications where DMU might be a precursor for functionalized materials, our R&D support can provide insights into optimal product integration. We pride ourselves on transparent communication, reliable supply chains, and responsive customer service, which have fostered strong relationships with leading manufacturers globally. With over a decade of experience in the fine chemical industry, we possess the institutional knowledge and operational agility to adapt to market demands and provide consistent, high-quality solutions, differentiating us in a competitive landscape.

Our commitment to quality for cas no 96 31 1 is evidenced by our robust quality management system, certified to ISO 9001 standards. Every batch undergoes comprehensive testing in our state-of-the-art laboratory, ensuring full compliance with technical specifications. We provide Certificates of Analysis (CoA) with each delivery, offering complete transparency on product purity, physical properties, and trace impurities. Our adherence to cGMP principles where applicable ensures suitability for pharmaceutical intermediate use, reflecting an authoritative stance on product integrity and safety.

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and any post-sales support. This commitment to comprehensive service underlines our trustworthiness and dedication to long-term client relationships. We understand that reliable supply and expert support are as crucial as product quality, especially for critical intermediates like 1,3-Dimethylurea.

This is the first article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.